1. Difference between crystalline and amorphous? Daily to see the solid is divided into two major categories of non-crystalline and crystalline, non-crystalline arrangement of atoms within the material is not necessarily the law of the fracture when the fracture is random, such as plastic and glass, and called the crystal material, represent the natural shape of a regular polyhedron, with obvious edges and corners with the plane, the atom is in accordance with its internal law must line up neatly, so when they break off the plane according to certain, such as salt, crystal and so on.

2. Difference between monocrystallie and polycrystalline? Some of the crystal is composed of many small grains, if the arrangement between the grains are no rules, this is called polycrystalline crystal, such as copper and iron. But there are also the crystal itself is a complete large grains, the crystal is called single crystal, crystal and crystal diamond.

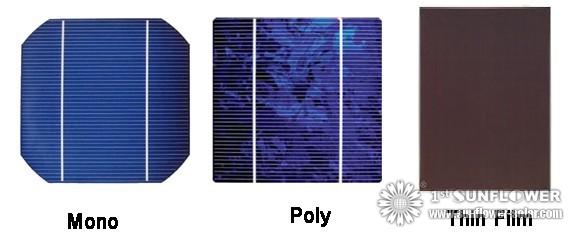

3. Monocrystalline silicon and polycrystalline silicon photovoltaic cells compare? Monocrystalline silicon cells with a cell conversion efficiency, good stability, but the cost is high. Low-cost polycrystalline silicon cells, the conversion efficiency slightly lower than the Czochralski silicon solar cells and materials in a variety of defects such as grain boundaries, dislocations, micro-defects, and material impurities carbon and oxygen, as well as the stained process transition metals.

The first is the advent of solar cell silicon solar cells. Silicon is very abundant on the earth, an element almost everywhere have the presence of silicon can be said to be used without silicon to make solar cells, indeed no shortage of raw materials. But it is not easy to extract, so people in the production of monocrystalline silicon solar cells, they also studied the polycrystalline silicon solar cells and amorphous silicon solar cells, has commercial-scale production of solar panel, also did not jump out of silicon series. In fact, the semiconductor materials for manufacture of solar cells a lot, along with the development of industrial materials, solar cells will be more and more varieties. Research and trial production has been the solar cell, in addition to silicon series, there are cadmium sulfide, gallium arsenide, copper indium selenium and many other types of solar cells, too numerous to mention, the following are a few of the more common solar cells.

Monocrystalline silicon solar cells

Monocrystalline silicon solar cells is currently the fastest developing a solar cell, its composition and production technology has been finalized, the products have been widely used for space and ground facilities. The high purity single crystal silicon solar cells as the raw material rod, 99.999% purity. In order to reduce production costs, and now solar terrestrial applications such as the use of solar-grade silicon rods, material performance has been relaxed. Some semiconductor devices can also be used for processing materials and discard ends of silicon materials, solar cells made by re-drawing a dedicated silicon rods. The slice of silicon rods, generally 0.3 mm thick slices. Wafer after forming, polishing, cleaning and other processes, made of silicon raw material to be processed. Solar cell processing chip, the first doping and diffusion in silicon, usually for the small amount of boron dopant, phosphorus, antimony and so on. Diffusion is the control into the quartz furnace for high temperature diffusion. And then using screen printing will be printed with a good paste made of silicon gate line, after sintering, also made of the back electrode and a gate line in the face of anti-reflection coating source, to prevent a large number of photons reflected from a smooth silicon surface, thus, single-chip silicon solar cells are produced. After single-chip random testing, according to the required specifications can be assembled into solar modules (solar panels), the method used in series and parallel to a certain output voltage and current, and finally with the framework and package materials package. According to the system user can design different size solar module solar cell composed of a variety of square, also known as the solar array. Current silicon photoelectric conversion efficiency of solar cells is about 15%, laboratory results have more than 20%. Also for the space station up to 50% or more solar panels.

Polycrystalline silicon solar cells

Monocrystalline silicon solar cell production requires large amounts of high-purity silicon material, the production of these materials, process complexity, power consumption drastically, the total cost of solar cell production has been over half, combined with the silicon rod was drawn cylindrical, sliced wafer production solar cells is to form a solar module surface low utilization rate. Thus, 80 years, some European and American countries, the development into a polycrystalline silicon solar cells. Polycrystalline silicon solar cells using current materials, mostly a collection contains a lot of single crystal particles, or silicon materials from waste materials and metallurgical grade silicon melt molded. The process is to select a resistivity of 100 to 300 ohms? Cm block of material or a polycrystalline silicon material end to end, after crushing, with the 1:5 mixture of hydrofluoric acid and nitric acid corrosion appropriate, and then spent neutral-ionized water rinse and drying. Quartz crucible installed polysilicon materials, the addition of appropriate amount of boron in silicon, release the casting furnace, heating and melting in a vacuum state. Melted insulation should be about 20 minutes, and then injected into the graphite mold, to be cooled slowly solidified, that have polysilicon ingot. The ingots can be cast cubes to be processed into square slices film solar cells can improve material utilization and easy assembly. Polycrystalline silicon solar cells and solar cell production process is similar to the photoelectric conversion efficiency of about 12%, slightly lower than the silicon solar cells, but the material is simple, to save power consumption, the total production costs low, so get a lot of development. As the technology was improved, the current conversion efficiency of polycrystalline silicon can also be reached around 14%.

Amorphous silicon solar cells

Amorphous silicon solar cells appeared in 1976 with a new thin film solar cells, monocrystalline and polycrystalline silicon solar cells it with the production method is completely different, very little silicon material consumption, lower power consumption, very attractive. Method of manufacturing a variety of amorphous silicon solar cells, the most common is the glow discharge method, as well as reactive sputtering, chemical vapor deposition, electron beam evaporation and thermal decomposition of silane method. Glow discharge method is a Dan Yingrong device pumped into vacuum, hydrogen or argon gas filled diluted silane, with the RF power heating, ionization of silane to form a plasma. Deposition of amorphous silicon film on the substrate being heated. If the silane were mixed in the amount of hydrogenated or hydrogenated boron phosphate can be N-or P-type amorphous silicon film. Substrate materials are generally made of glass or stainless steel. Preparation of amorphous silicon thin film technology which depends mainly on the strict control of pressure, flow rate and RF power, the temperature of the substrate is also very important. The structure of amorphous silicon solar cells there are different, which has a structure called the PiN better battery, it is first deposited on the substrate N-type layer of amorphous silicon doped with phosphorus, and then deposited a layer of undoped i layer, and then deposited a layer of P-type boron-doped amorphous silicon, and finally a layer of electron beam evaporation of antireflection coatings, and deposition of silver electrodes. This production process, a series of deposition chamber can be used in production form a continuous process to achieve mass production. Meanwhile, the thin amorphous silicon solar cells can be made into laminated type, or use to manufacture integrated circuits in a plane, with the appropriate mask technology, a production of multiple batteries in series to obtain higher voltage . Because the average crystalline silicon solar cells around a single voltage of 0.5 volts, and now the production of amorphous silicon tandem solar cells in Japan up to 2.4 volts. The current problem is that of amorphous silicon solar cell conversion efficiency is low, the international advanced level of about 10%, and is not stable enough, often decline down conversion efficiency of the phenomenon, so not a lot of use for large-scale solar power, but mostly with in low light power, such as pocket electronic calculators, electronic watches and clocks and copier and so on. Failure to overcome the drop in efficiency issues, the amorphous silicon solar cells will promote the great development of solar energy, because its low cost, light weight, easier application, it can be combined with the housing of the roof form independent power of households.

In the fierce sun, single crystal solar panels can be transformed more and more non-crystal-type solar energy to electricity more than doubled, but unfortunately, the price of single crystal type of non-crystal-like than the two or three times more expensive, and in the case of non-cloudy Instead, the crystal-type transistor can be almost as much to collect solar energy.