Feature

1)It adopts the no welding line with the blue diamond internal bladder, and the lifespan is especially long.

2)For the all closed separated tank, the rated pressure is 0.6Mpa.

3)It adopts the super thick insulation layer, because it can keep warm and save electric energy.

4)It adopts the one-way anti-over pressure device, if the pressure is more than 0.6Mpa, the relief valve can reduce pressure and overflow automatically, so that the dirt in the tank can be drained easily.

5)Temperature pressure relief valve can protect overpressure.

(6)The controller imported from France, which can start heating and cut off when the temperature over heat automatically, besides, the two poles could moved at the same time.

7)When the leakage of the electric current is more than 10mA, it could cut off the electrical source automatically in order to keep safe.

8)There is the anode magnesium bar inside the tank to extend the lifespan.

9)The product adopts the national standard of the GB4706.12

10)The separated tank is especially suitable for water use of houses, hospitals, schools and the hotels.

Points for Attention

For your safe, please make sure pay attention to following items:

Forbid putting through the power if the water is not full in the tank, otherwise the tank will be damaged.

You have choice for using the AC 220V~/50Hz or the AC 110V~/60Hz

The ammeter, electric wire, the socket that connected with the separated tank must meet the demand of specified electric current of separated tank.

The plug and socket of the separated tank must be connected firmly.

In cold areas, if you don’t use the water heater for a long time in winter, please keep the bladder empty, in case the water inside will be frozen and damage the tank.

When heated, please don't close the cold-water stop valve, in order to lengthen the lifespan of the tank.

It is suggest that operate the temperature / the operation pole of the pressure relief valve by hand frequently, in order to avoid the relief valve and the valve seat carding being blocked and cause danger.

When use the separated tank, if the enactment temperature is higher than 60°C, you must make the cold water and hot water mixed, so as not to scald, especially to the elder and children.

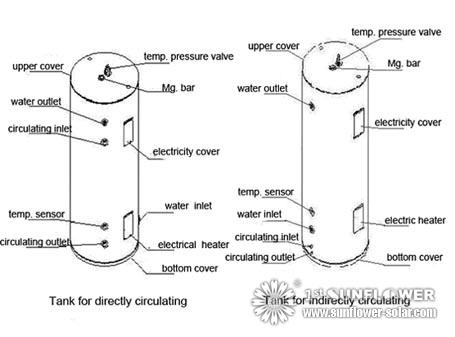

Structure sketch map

Description

(1) The place of installing the water heater must be closed to the place of using, the temperature / pressure relief valve, temperature controller and electric heat pipe must be faced the direction where is easy to maintain. The data plate should be easy to read, and the space above the tank should be over the height of the tank so as to check and change the positive pole protection device.

(2) The space around the tank should be convenient when pulling down the whole tank to maintain or change the parts in case of necessity.

(3) The tank is with vertical type; it must be installed in the level that can bear the weight of the product.

(4) Power socket must be installed in the position that the water can’t spray, so as not to produce vapor when taking a shower, then induce the socket leak electricity.

(5) When heated, it is normal phenomenon when there is a little water draining from the overflow /pressure relief valve. And you could connect with a water pipe with the overflow, and the other end to the safe water place, so as not to be scalded.

(6) The overflow should be kept open and down.

(7) The pipeline connection.

A. The connection of cold water pipe:

The cold-water outlet is closed to the bottom of the power covering, and the interface is G1/2”. First, connect the one-way safe drainage valve with the water heater, then join the close valve and connect with tap water pipe.

Note: When the pressure in the tank reaches some value, the one-way safe drainage valve can unload the pressure to tap water pipe automatically. So when you electrify to the tank, please keep the cold close valve open.

B. The joining of hot water pipe:

The hot water outlet is on the top of the tank, and the interface is G1/2”.

After connecting the close valve in the outlet pipe of the hot water, then use the tube in order to lead hot water to the place of the hot water requirement.

C. The installation of temperature/ pressure relief valve:

Twine the whorl well with the crude airproof strap, but it can't over the whorl terminal surface, then fasten temperature / pressure relief valve in the installation place. Note that the overflow should face underside so the water comes out conveniently.

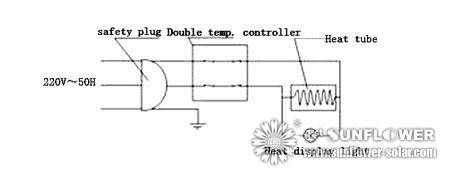

Diagram of electric appliance schematic

Usage

(1). Water supply:

First, open the close valve of the outlet of the tank and one hot faucet, and keep the water pipeline open. When the hot faucet works normally, which means water is full and then you could close the faucet.

(2). Settlement of hot water temperature:

The temperature regulation range of the temperature controller of the tank is 30~75℃, and the set temperature at 65℃ before dispatched from the factory.

Warning: Please pay attention to the scalding dangerous of the hot water, especially for the children and elders.

(3). Inserting the plug:

There must be good earth and three feet when you use the plug, and make the socket and power dry. The electric current that the outlet and wire allow passing is more than the one of the nominal current of the water heater.

(4). Using of hot water:

After heating to the established temperature, the power showing light will be put out, and then the water heater will be the state of keeping warm automatically. At this time, you can use the hot water, and obtain the suitable temperature by mixed regulating with the cold faucet. The cold water in the water heater willsupplement automatically while using the hot water, at the same time the temperature controller will set up an electric circuit to heat automatically. If you don’t use the water in the short time,

Please don’t close the power of the tank because its good performance of keeping warm doesn’t waste too much electricity.

(5). Close the water heater:

Close the power first, and then close the hot water globe valve of the water heater.

Warning: Forbid regarding the debugger on the safety plug as the switch, we must pull out the safe plug.

Maintain

In order to make sure the tank work normally and efficiently, you should keep maintain regularly, and remove the dirt from the water. If you use the one-way safety drainage valve,please cut off the electric source, close the water inlet valve, open the outlet valve, and operate the drainage handle.(See the picture) to drain the dirt. After this procedure is finished, make sure that the tank is full of water, then put the current though.

(2). Change the magnesium bar

Propose to check the magnesium bar once after installation and using the water heater for two years; you must change it if the magnesium bar is run out.

Trouble Shooting

(1) No water comes out

A. Check the tap water to see whether the water supply is cut off or not, or the water pressure is too low.

B. Whether close valve of the water supply tube is open

C. Whether each interface is blocked or not.

(2) The water temperature is too low:

A. Check the setting temperature if it is too low, or maybe the specification of the water heater you choose can’t meet your need. So you must choose the specification according to the actual consumption.

B. Check the regulation proportion of the mixture –water valve if it is normal.

(3) Temperature/ Pressure relief valve is leaked:

(1). Working normally: It is the normal phenomenon that there’s a little water, which discharge when heated.

(2). Leaking continually:

Try to lift the temperature / pressure relief operating pole upwards gently for several seconds, which can dispel some small impurity and fix the breakdown, and then slack off the operating pole.

(3). Pouring water continually for long time:

It states the pressure of the running water is higher than the one of the regulated pressure of the water heater sometimes. Please ask the installing worker to fix a limited pressure valve.

Warning: Forbid to replace the original safety valve with a higher set pressure safety valve.